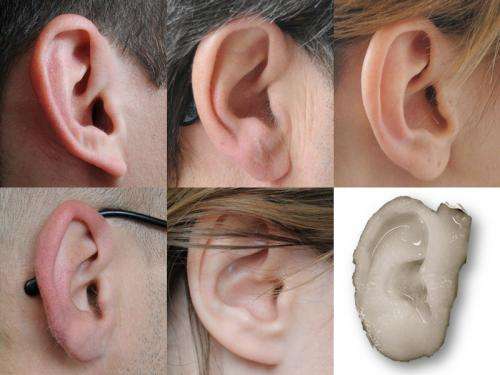

An ear with the right look and feel

(Medical Xpress)—Like a fingerprint, their shape is so characteristic that one can identify us by them. The outer part of our ears has a complex structure that surgeons have a hard time replacing when disease or accident robs us of an ear. ETH researchers have found a way to produce an ear replacement with the right look and feel.

The ear is a complex organ, not only the hidden inner parts but also the outer area, the auricle. As the major part of the auricle consists of cartilage, a tissue that contains neither nerves nor blood vessels, it cannot regenerate after injury. Reconstructing an ear remains a challenge for surgeons, especially as patients want the ear replacement to resemble their original one not only in looks but also in feel.

An international team involving Kathryn Stok, researcher at the Institute for Biomechanics, has characterized the mechanical properties of ear cartilage and applies this knowledge to develop auricle implants. Stok and her PhD student Luc Nimeskern analysed how strong and stiff the cartilage of an ear needs to be. They performed mechanical tests, measuring the flexibility of ear cartilage and drawing a "map" of the mechanical properties of different parts of the human ear. In parallel, they tested a novel biomaterial's performance in the same mechanical tests to learn how the biomaterial must be tuned to match the characteristics of a real ear.

Fine-tuning the texture

The biomaterial consists of a web of nanocellulose fibres spun by a certain kind of bacteria, Gluconacetobacter xylinus. "The bacteria build this web naturally to create an environment in which they can protect themselves", explains Héctor Martínez Ávila, a visiting PhD student from Chalmers University Göteborg. He works with Stok and Nimeskern on testing and characterizing the material that is produced in Göteborg. "One of the advantages of the material is that we can tune it to render softer and stiffer parts, like in a real ear", describes Stok. Another advantage is that it is well tolerated by the human body.

Using the data from their measurements, the researchers succeeded in producing an ear replacement. By first scanning a patient's healthy ear using Magnetic Resonance Imaging, they created a silicon mould by 3D-printing in which they allow the bacteria to weave their web of nanocellulose. They varied the stiffness of the material by either compressing the material to yield more rigid parts or by inserting bubbles of gel as placeholders to produce softer, parts.

After removing both the bacteria and the gel by an extensive washing procedure, the scientists use the resulting structure as a "scaffold" for cartilage cells. In a culture dish, these cells settle onto the material and into its pores. Supported by this framework the cartilage grows into the desired shape. The material thus serves two functions: as a scaffold for re-growing the tissue and as an implant material that supports the newly formed auricle.

Exact imitation

This new approach allows a more exact reconstruction of an auricle than the currently applied methods. When surgeons reconstruct an ear these days, the procedure relies on their artistic skills. They take a piece of cartilage out of one of the patient's ribs and carve it into shape. When this piece is implanted underneath the skin, the body grows connective tissue that joins the cartilage with the skin. As the new ear lies completely underneath the skin at this point, the surgeon has to "free" it in an additional surgery so it stands freely off the head like a healthy ear. Not only can this procedure ruin one of the patient's ribs but also the shape of the new ear depends on the surgeon's skills. Artificial materials currently in use that allow a higher degree of control over the shape are either too soft or too stiff, causing discomfort or even complications.

As the bacterial nanocellulose can be shaped as the exact mirror image of a patient's healthy ear and its stiffness can be tuned accordingly, the researchers expect the material to advance to clinical application in the near future. "The ear has a very complicated shape compared to other body parts made of cartilage. Once we have established the procedure for the ear, it could be used for any cartilage tissue." The highest demand would probably be in joint cartilage, for instance in knees, thinks Stok, but also nose, throat and spinal discs consist of cartilage.

More information: Nimeskern, L. et al. Mechanical evaluation of bacterial nanocellulose as an implant material for ear cartilage replacement. J Mech Behav Biomed Mater. 2013 Jun;22:12-21. DOI: 10.1016/j.jmbbm.2013.03.005