Systems engineer helps identify bottlenecks in blood poisoning care processes

Blood poisoning, known as sepsis, is the most common cause of death in intensive care units, according to the National Institutes of Health. The body's immune response to fight the infection triggers inflammation that restricts blood flow and leads to multiple organ failure.

The health-care team's goal is to return the patient's central venous oxygen saturation level to at least 70 percent within six hours or less, explained professor Huitian Lu of the South Dakota State University Department of Construction and Operations Management. If that doesn't happen, "the patient mortality will be high—the first six hours are critical."

Health care professionals recommend completing a series of care processes called the sepsis resuscitation bundle within six hours after diagnosis.

However, only half of the sepsis patients receive all elements of care needed within the recommended six-hour window, according to a study conducted Dr. Yue Dong and Dr. Ognjen Gajic of the Mayo Clinic College of Medicine in Rochester, Minnesota.

Lu collaborated with the researchers through the Mayo Clinic Multidisciplinary Simulation Center and the Multidisciplinary Epidemiology and Translational Research in Intensive Care group to identify bottlenecks in the sepsis resuscitation delivery process.

Analyzing system design

Lu worked with Dong and Gajic to analyze the problems from a system design perspective considering factors such as scheduling and workflow, rather than solely focusing on treatment itself. Then he applied root cause analysis to examine the existing processes and identify sources of delays.

"This is a statistical methodology used in systems engineering, which I am applying to health-care delivery operations," Lu said.

The researchers used data from 600 sepsis cases and examined 15 key processes within the sepsis resuscitation bundle.

They relied on observations, electric medical records with time stamps and the provider's best estimation to determine how much time each task consumed.

Using these numbers, the researchers built a computer model which they verified using real data. "It was not perfect because we lacked detailed process data, but it was good enough for the statistical analysis we were doing," Lu said.

Pinpointing bottlenecks

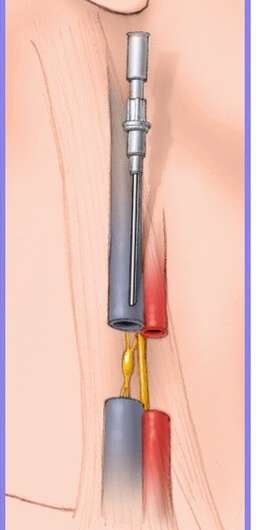

Through discrete event simulation, Lu pinpointed the tasks that took the most time. His simulations showed that bottlenecks occurred with X-ray, lab work and placement of a catheter into a central vein, usually in the neck. For example, 20 minutes could be saved by having an experienced critical care fellow insert the catheter.

Based on his analysis, Lu reported that changes in six areas may reduce the total average patient treatment time by 31.8 percent, improving the sepsis resuscitation bundle compliance rate from 50 to 71 percent.

"Completing the procedures in six hours will give the patients the best chance of survival," Lu pointed out. But unlike a manufacturing situation, the outcome also depends on many unpredictable individual patient variables.