Innovative coating on medical devices fights bacterial infections

Georgios Sotiriou, principal researcher at the Department of Microbiology, Tumor and Cell Biology, and his colleagues have developed a durable coating for medical devices which is activated by light, providing on-demand disinfection.

The findings are presented in the Chemical Engineering Journal, and the researchers discuss some of their findings here.

What are the most important results you present?

The most important results are that we have developed a functional light-triggered coating for medical devices that is very durable (stays there and retains its properties) and can destroy bacterial biofilms. Light-triggered photocatalytic coatings destroy biofilms on-demand, but the challenge so far has been two-fold: first it is difficult to find materials that are activated by white light (and not harmful UV light) and second, to have them stable on medical devices and retain the activity over several cycles.

Why are these results important, do you see any potential applications?

The results are important because we now show how we have addressed the major two challenges above. Here we tackle both of these major challenges by producing materials that can be activated with white light and also invent a new method to make these coatings highly durable enabling them useful in repeated treatments. The potential applications are for such coatings to be employed on medical devices that are often colonized by bacteria, such as catheters, endotracheal tubes, and wound dressings/meshes.

How could your study influence patient care and treatment?

Biofilm infections tantalize several patients and the innovation here could mitigate this global health challenge by reducing such infections. Especially when such infections occur in immunocompromised patients, the clinical benefit is very high.

How did you conduct the study?

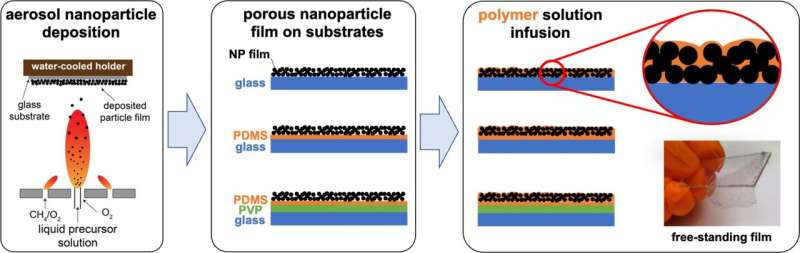

We produced the photocatalytic nanoparticle coating by a highly versatile nanomanufacturing technology, flame aerosol synthesis, and deposited them as porous films on the surface of the medical device. Then we infused this porous nanoparticle film with silicone (a polymer often used in medical devices) with a precise thickness. That dramatically increases the durability of the produced coating. Then we grew bacterial biofilms on this medical device—mimicking surfaces. The devices were then briefly (15–90 min) irradiated with white light which resulted in the on-demand biofilm destruction.

What is the next step in your research?

We have filed a patent application for this invention and we now try to perform further product development to assist in the rapid translation to the clinics. The next steps would be to develop this technology further as a coating on existing medical devices such as catheters, endotracheal tubes, and wound meshes/dressings, to name a few examples.

More information: Eleni Bletsa et al, Highly durable photocatalytic titanium suboxide–polymer nanocomposite films with visible light-triggered antibiofilm activity, Chemical Engineering Journal (2022). DOI: 10.1016/j.cej.2022.139971