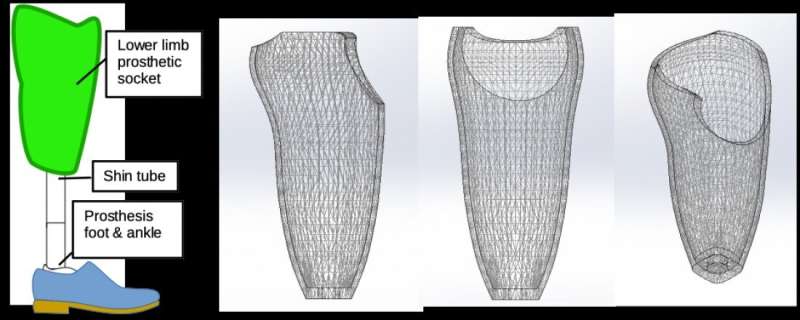

Drawings of the lower limb prosthetic socket. Credit: Newcastle University in Singapore

Universiti Malaysia Perlis and Newcastle University researchers have partnered up to make a low-cost lower limb prosthetic socket using locally derived natural fibers from agricultural waste, that would directly benefit the economy of the local community. This project is part of a joint research program between the two universities that was awarded a prestigious Research Environment Links (REL) grant as part of the Going Global Partnerships program managed by the British Council with Malaysian Industry-Government Group for High Technology (MIGHT). The REL grant provides financial support for capacity-strengthening and collaboration activities to develop and sustain medium to long term relationships proposed by applicant institutions in partner countries and the UK. The project is led by Associate Professors Mohd Shukry Abdul Majid and Fauziah Mat from the School of Mechatronic Engineering, UniMAP, and Professor Tom Joyce, and Associate Professor Kheng Lim Goh from the the Faculty of Science, Agriculture and Engineering, Newcastle University.

"The UniMAP has outstanding people, excellent facilities and is well known for composite material research expertise under the strong leadership of Assoc. Prof. Shukry," says Prof Tom Joyce. "We are delighted to be able to partner with the UniMAP team to work on this project for the benefits of the many people who need lower limb prosthetics."

Specifically, Assoc. Profs Shukry and Fauziah are working on the project, assisted by a research assistant, to exploit natural fibers, such as kenaf fibers or pine apple leaf fibers (generated as agricultural waste from the agricultural industry), for use in reinforcing plastics that are used to make the lower limb prosthetic socket. UniMAP has significant expertise creating novel composite materials from synthetic and natural fibers for applications in the marine, land transport and construction industry.

"The current prosthetic sockets are made from a mold that is derived from the residual limb. This ensures that the best possible design with a comfortable and effective fit can be achieved. The prosthesis is laminated by carbon or glass fibers reinforcing plastics, which are lightweight and offer good flexibility." says Assoc. Prof Shukry.

However, as the world grapples with the targets of COP26, such as moving away from our reliance on oil and gas, which are the main sources from which plastics and carbon fibers are derived, the materials for making the prosthetic sockets will become more expensive as they become harder to obtain. The focus of the REL project is about the use of natural fibers derived from waste generated from the local agricultural industry, to replace the synthetic fibers for reinforcing the plastic sockets, as a viable medical device. Because the making of the prosthetic socket is so complex, and there are many stages in the production process, even the idea of introducing natural fibers may not simply lead to lowering the negative impact on the environment. Every product has a life cycle, and every stage in the cycle can consume energy, produce solid wastes and emits green house gases. The prosthetic socket is created, sold, used and then disposed of. At the end of its useful life with one consumer, it could not be reused by another consumer. It may, however, be recycled or sent to the waste stream. In the case of the latter, the plastic (and natural fibers) materials and the energy used to make the device are lost. Thus, making the device recyclable could save both materials and energy. Newcastle University researcher Assoc Prof Goh's part involves conducting the life-cycle assessment to identify the environmental impact of the prosthetic device at every stage of its life cycle. The aim is to identify opportunities to reduce the overall impact of the device. While conducting a life-cycle assessment is not straight-forward, ensuring that the prosthetic device meets the requirement of the medical device regulatory body is also challenging. Prof. Joyce is a respected authority in medical device technology who has a knack for discovering problems and the cause of problems in medical devices, before it gets too late. He will provide invaluable expert guidance to the team in ensuring that the environmentally friendly prosthetic leg achieves regulatory approval and thus becomes available to the people who need them.

Regarding the new design, Assoc Prof Goh says "we will embrace an ecologically sustainable approach, with no waste build-up anywhere; leftover materials energy from one product stage will become raw materials for other industry. The best part of this is that the feasibility study will help to bring out novel ideas that if carefully put together could potentially represent a step-change approach to the development of the green prosthetic socket."

"By virtue of its economy, Perlis produces a lot of agricultural waste, such as pine apple leaf fibers. Given that the natural fibers are sequestrated carbon, there are advantages of turning the fibers to good use from a sustainability perspective. This will not only meet the objectives of UN SDG 12 for responsible consumption and production but also raise our ambitions to establish an ecosystem that embraces the local processing and supply of the natural fibers, fabrication of the prosthesis, and finally, the recycling industry, all of which could be carried out by the local workforce," says Assoc Prof Goh.

Provided by Newcastle University in Singapore