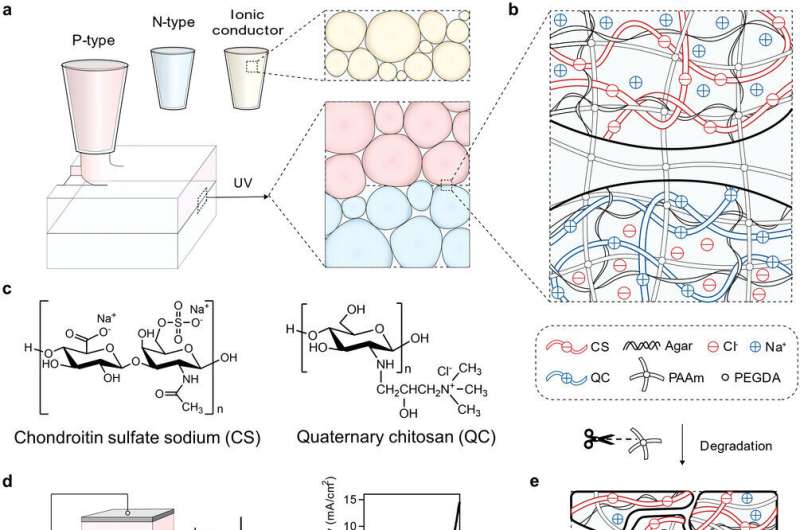

3D ionic microgel printing (3D IMP) of double-network transient ionic junctions. a) Schematic of 3D IMP with modular ionic microgel inks, including p-, n-type, and ionic conductor units. b) Schematic of the transient ionic junctions formed with ionic microgels fused with a secondary PAAm network. c) Chemical structures of the highly charged and biodegradable biopolymers used as dopants in the p-type (CS) and n-type (QC) units. d) A single ionic junction functions as an ionic diode, exhibiting an asymmetrical current–voltage behavior. e) Schematic of transient ionic junctions undergoing degradation. f) Digital images of a printed transient ionic circuit. g) Digital images and h) dry weight loss showing in vitro degradation of printed ionic junctions in DPBS; the hydrogel with MBAA as crosslinker for PAAm network is included for comparison. Scale bar, 0.3 cm. Data are expressed as the mean ± SD from n = 4 samples. Credit: Advanced Functional Materials (2023). DOI: 10.1002/adfm.202213677

McGill researchers are exploring a new technique that uses 3D printing and hydrogels. It has the potential not only to improve biomedical implants but could also be useful in the development of human-machine interfaces such as touch screens and neural implants. Biomedical devices like pacemakers or blood pressure sensors that are implanted into the human body need to be fabricated in such a way that they conform and adhere to the body—and then dissolve at the right time.

Using 3D printing and hydrogel technology, researchers in McGill University's Department of Engineering are moving closer to being able to create devices that better match the human body than the electronic devices currently in use.

The researchers say this emerging technology, called soft ionotronics, has the potential to be used to improve wearable and implantable biomedical devices. For example, patients in neuromuscular rehabilitation could benefit from soft and stretchable strain and pressure sensors that can be adhered to their joints. The article, "Tough Transient Ionic Junctions Printed with Ionic Microgels" by Ran Huo and colleagues, was published in Advanced Functional Materials.

"Compared to traditional manual fabrication methods, 3D printed ionic junctions can have much better shape fidelity and smaller sizes. Shape fidelity is important for any device to function in the way it is designed. The smaller size means more ionic junctions can be included in one single device of limited size," said Ran Huo, lead author on the study and Ph.D. candidate in McGill's Department of Engineering.

More information: Ran Huo et al, Tough Transient Ionic Junctions Printed with Ionic Microgels, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202213677

Journal information: Advanced Functional Materials

Provided by McGill University