This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Monoclonal antibodies from space: Improved crystallization under microgravity during manufacturing in orbit

Monoclonal antibodies (mAbs) have revolutionized cancer therapy due to their ability to specifically target tumor cells while sparing healthy ones. These biologics have become indispensable in treating various cancers, offering improved specificity and fewer side effects compared to traditional chemotherapy.

A review published in the Journal of Exploratory Research in Pharmacology explores this topic.

Traditionally, mAbs are administered intravenously (IV) in clinical settings, requiring repeated treatments over extended periods, which can be burdensome for patients and health care systems. Recently, there has been a shift towards subcutaneous (SC) administration, which offers greater convenience and compliance.

SC administration allows patients to self-administer treatments at home, reducing hospital visits and improving their quality of life. However, SC administration faces challenges such as limited dosing volume and increased viscosity of mAb formulations, necessitating novel approaches to formulation development.

SC administration of mAbs is restricted by the maximum injectable volume (typically up to 2 mL) and the high viscosity of concentrated formulations. These factors complicate the development of SC mAb products, as higher concentrations often lead to increased viscosity and stability issues. The need for highly concentrated mAb formulations for SC delivery is growing due to the potential for less frequent dosing and improved patient adherence. Managing the viscosity of these formulations is critical, as excessively viscous solutions can cause discomfort during injection and affect the bioavailability of the drug.

One promising solution to these challenges is the crystallization of mAbs, which can form colloidal suspensions with lower viscosity compared to their solution counterparts. Crystallized mAbs, such as Infliximab at 150 mg/mL, demonstrate acceptable viscosity levels and favorable pharmacokinetic profiles, which can be advantageous for certain therapeutic approaches. Crystallization not only reduces the viscosity of the formulation but also enhances the stability and shelf-life of mAb formulations. This stability is particularly beneficial in regions where maintaining a cold chain for drug storage and transportation is challenging.

The microgravity environment of space offers unique advantages for protein crystallization. High-quality, large, and uniform mAb crystals can be produced under microgravity, which are often superior to those formed on Earth. The absence of sedimentation and convection currents in microgravity leads to more orderly crystal growth, resulting in crystals with fewer defects.

This improved crystallization process can lead to better therapeutic efficacy and reduced immunogenicity of mAb formulations. Furthermore, microgravity-induced crystallization could streamline the manufacturing process and improve the scalability of producing crystallized mAbs for SC administration.

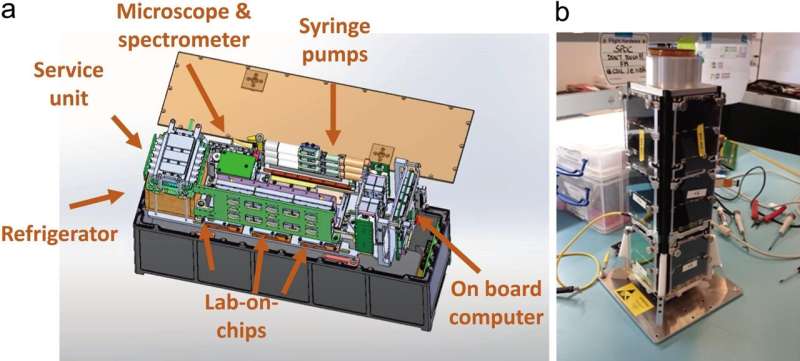

Several methods are available for protein crystallization, including vapor diffusion, dialysis, and batch techniques. Vapor diffusion, using either the hanging-drop or sitting-drop methods, is the most commonly employed technique. This method involves equilibrating a droplet containing a mixture of protein and precipitant against a reservoir of precipitant, facilitating the formation of high-quality protein crystals. Utilizing these established crystallization techniques in a microgravity environment could further enhance the quality and consistency of mAb crystals. The controlled environment of space-based laboratories provides an ideal setting for optimizing crystallization conditions and scaling up production.

The shift towards SC administration of mAbs represents a significant advancement in cancer therapy, offering greater convenience and compliance for patients. However, the challenges associated with high-concentration mAb formulations necessitate innovative solutions such as crystallization. The unique conditions of microgravity present a valuable opportunity to improve the crystallization process, resulting in superior mAb formulations with enhanced stability, efficacy, and patient accessibility.

Continued research and development in this area are essential to fully realize the potential of crystallized mAbs in modern biotherapeutics. By leveraging the benefits of space-based crystallization, the biopharmaceutical industry can develop more effective and patient-friendly treatments, ultimately improving outcomes for cancer patients worldwide.

More information: Shimon Amselem et al, Monoclonal Antibodies from Space: Improved Crystallization Under Microgravity During Manufacturing in Orbit, Journal of Exploratory Research in Pharmacology (2024). DOI: 10.14218/JERP.2023.00020