Is it possible to detect and assess neuromuscular functions via wearable, soft yet durable strain sensors?

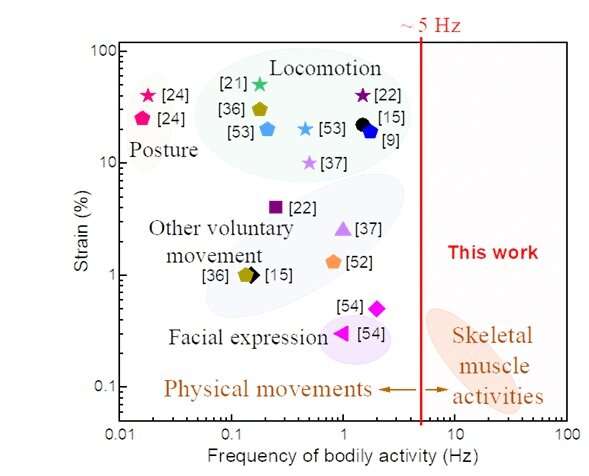

Simultaneously achieving ultra-softness, ultrahigh sensitivity and mechanical resiliency is a major challenge for wearable electronics and soft machines. The soft yet wearable sensors with their mechanical properties well matched with that of the soft human skin have largely fulfilled the demands for achieving the high-fidelity and real-time detection and assessment of different bodily movements remotely. However, as restricted by the intrinsic viscoelasticity of conventional soft materials, current wearable sensors based on soft materials are primarily utilized for monitoring low-frequency and relatively large bodily motions. Detection of subtle and fast neuromuscular functions with a soft material is crucial for the design of highly sophisticated wearable electronics but still remains a challenge.

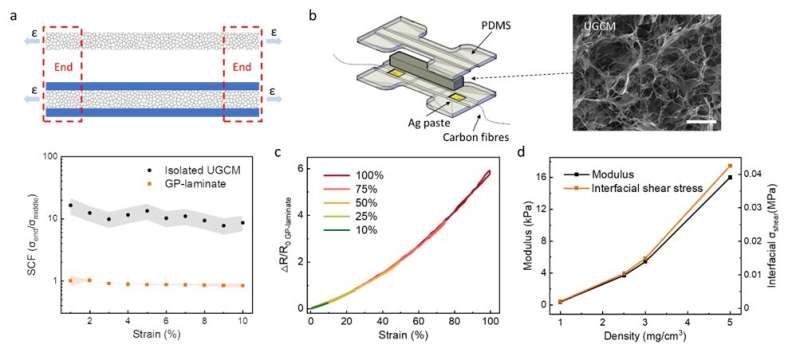

In a paper published recently in National Science Review, an international multidisciplinary team present a new design to tackle this challenge. By taking the advantage of their previous discovery about the unique mechanical and electromechanical properties of the ultralight graphene-based cellular materials (UGCMs), they discovered that the UGCM possesses a unique interfacial stress transfer mechanism when being in contact with a rubber material. They found that unlike the traditional electroconductive aerogels, ultralow density UGCMs ( ~ 1 mg/cm3) were able to conformably deform with the rubber layer up to 100% strain. This discovery not only endows the intrinsically fragile UGCMs with large stretchability by simply wrapping them with a rubber outer layer (forming the GP-laminate); but also provides a new method to retain the unique dynamic electromechanical property of the UGCM within the hybrid structure. The resultant GP-laminate exhibits a highly sensitive and broadband frequency resistance response (>180 Hz) for a wide range of strains.

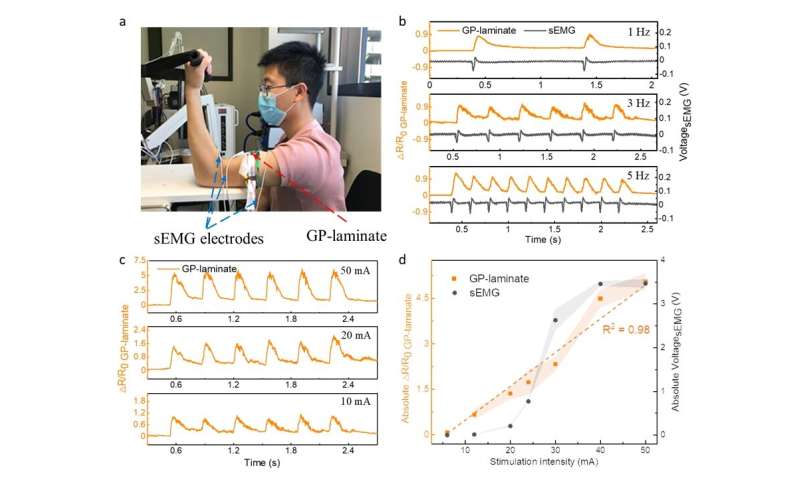

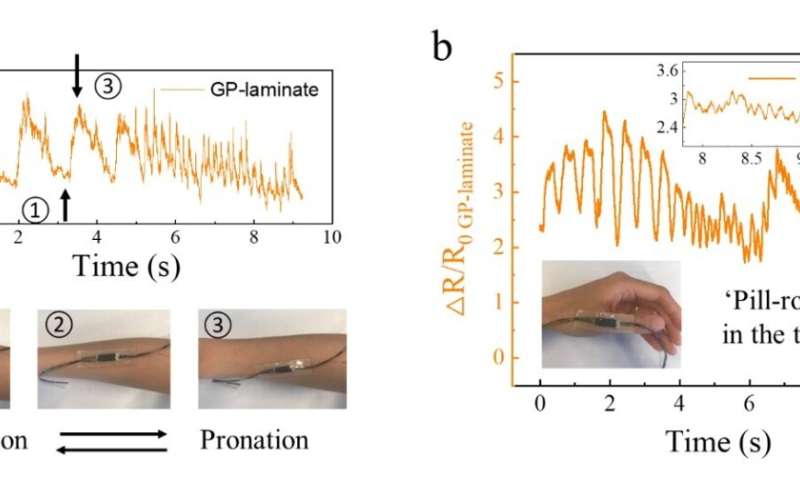

The team, working with experts from different disciplines, sought to further explore if such UGCM/rubber composites were able to monitor the subtle and fast neuromuscular functions. The team performed the clinical tests on human subjects and confirmed the accuracy of GP-laminate for monitoring different skeletal muscle groups with the traditional, bulky and costly technique—electromyography (EMG) as the reference. The EMG technique has long been used for monitoring muscle functions. The team found that, during either electrically or voluntarily evoked muscle contractions, the GP-laminate showed highly consistent signal response to EMG at different intensity and frequency ranges. This further allow the assessment for neuromuscular movement disorders, such as Parkinson's and tremors. This study is conducted by Dr. Zijun He under the supervision of Prof. Dan Li (Chemical Engineering, The University of Melbourne) and A/Prof. Ling Qiu (Tsinghua Shenzhen International Graduate School, Tsinghua University).

-

(a) A photo of attaching GP-laminate and sEMG on to the bicep muscle group for skeletal muscle contraction detection. (b) A comparison of the recorded relative resistance changes of the GP-laminate (orange curve) and voltage outputs of the sEMG (black curve), which refers to the muscle action potential, in response to the evoked biceps muscle contractions at different frequencies of 1 Hz (top), 3 Hz (middle) and 5 Hz (bottom). (c) The relative resistance changes of the GP-laminate in response to the evoked biceps muscle contractions when the stimulation intensity was adjusted at 50 mA (top), 20 mA (middle) and 10 mA (bottom). The stimulation frequency was set at 3 Hz. (d) A comparison of peak-to-trough values of the relative resistance changes of the GP-laminate (orange dots), denoted as the 'absolute △R/R0 GP-laminate', with the peak-to-peak range changes of the recorded muscle action potential from the sEMG (black dots), denoted as the 'absolute Voltage sEMG', in response to the evoked biceps muscle contractions at different stimulation intensities from 6 mA to 50 mA. Credit: Science China Press -

(a) and (b) Parkinsonian tremor detections manifesting as (a) Pronation or supination in the forearm and (b) 'pill-rolling' in the thumb. The insets in (a) show the arm position changed from supination to pronation with corresponding signals highlighted in the resistance changes of the sensor. The bottom left inset in (b) demonstrates the 'pill-rolling' disorder detection by using the strain sensor in the thumb. The top right inset in (b) shows the zoom-in the output signal of the strain sensor within the last 2 s. Credit: Science China Press

More information: Zijun He et al, Detecting subtle yet fast skeletal muscle contractions with ultrasoft and durable graphene-based cellular materials, National Science Review (2021). DOI: 10.1093/nsr/nwab184