This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Tailor-made implants for patients thanks to simulations using virtual human modeling

Patients requiring artificial hip and knee replacements are increasingly younger. Because they are more physically active than older patients, the risk of requiring a second operation is considerably higher. Researchers at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA are addressing this problem with a new software platform for virtual clinical in silico studies.

With the help of computer-assisted functional tests and innovative human modeling, implants and orthoses can be designed specifically for an individual—minimizing later complications. The workflow-based simulation environment for virtual product development and research in orthopedics will be presented at the joint Fraunhofer booth (Hall 3, Booth E74) at MEDICA, taking place in Düsseldorf between November 13 and 16, 2023.

Recent studies show that the number of young people with artificial joints is on the rise. There are various reasons for this, including rheumatic diseases, obesity, congenital bone defects and deformities and even damage caused by tumors. Both life expectancy and the desire for mobility are increasing, posing tough challenges for both endoprosthetic and exoprosthetic solutions.

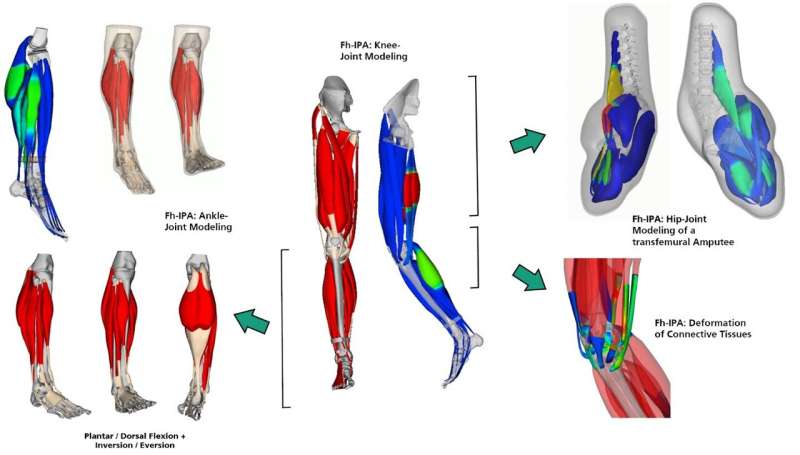

With a novel in silico human modeling platform for the research and development of orthopedic medical devices, the In-Silico Orthopedics research group at Fraunhofer IPA in Stuttgart is tackling these challenges head-on. The group is digitalizing numerous manual production steps and transferring them to a virtual process, making it possible to use the simulation software to manufacture all types of joint replacements, prostheses and orthoses that are tailored to the individual patient in a sustainable, fast and precise way, all while meeting strict quality standards.

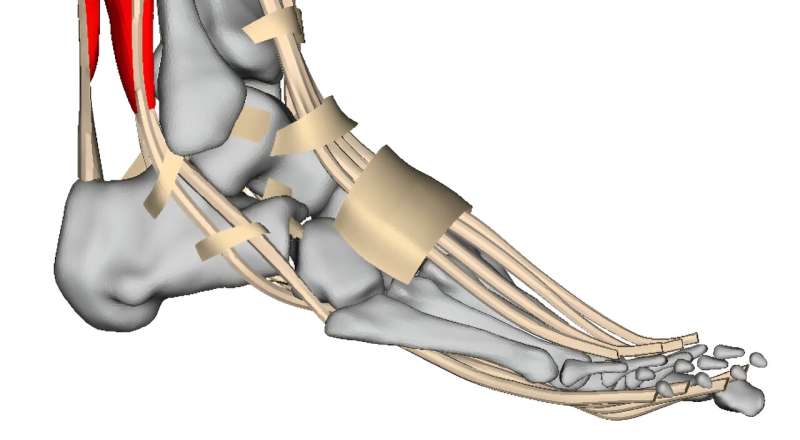

Among other things, this is supported by one-of-a-kind, individual musculoskeletal human modeling for orthopedics, generated from medical imaging data from processes such as MRI and ultrasound. The muscle-tendon system is modeled with every possible detail, creating what is essentially a digital twin—a likeness of the patient.

With the help of this 3D finite element modeling, the biomechanical characteristics of the muscles, tendons and connective tissue structures can be simulated with realistic physiological dynamic movement both before and after an implant is fitted.

Platform helps surgeons plan operations

Plastic surgery will also benefit from the new solution: Patients with neuromuscular diseases such as cerebral palsy often suffer from muscular dysfunction in their ankle joints. If this can no longer be treated conservatively, ankle joint correction requires a muscle or tendon transfer (e.g., from one toe to another) or tendon lengthening to readjust the delicate muscular balance. The surgeon can test the effects of these interventions prior to operation using the in silico human modeling platform, where they are able to alter various parameters, including geometry, direction, position, load and length. By doing this, the surgeon can avoid overcorrection, for example.

"Our software platform supports surgeons in planning procedures. Using the realistic simulations, they are able to see precisely what effect each change has," explains Dr. Okan Avci, head of the Virtual Orthopedic Lab at Fraunhofer IPA. "This preserves the knowledge of experienced doctors. Surgeons with little experience can use the software to learn. It is also a way to improve standards, since we are establishing a system that is easy to understand."

Helping 500 patients instead of 50 using virtual clinical studies

Another application for the software platform is virtual clinical trials. Patient-specific analyses of implant functionality and effectiveness are currently hardly ever used in clinical trials as they are too expensive and complex. This is because putting together suitable patient groups, known as cohorts, often proves difficult. It is rare to find more than 50 subjects. However, the new Medical Device Regulation (MDR) now requires the effectiveness of prostheses to be determined. The EU Commission tightened this aspect of the MDR in May 2021.

The number of knee and hip endoprostheses has risen dramatically, with the rates for first revision procedures in Germany being highest in under 65s—at 100% in men and 41% in women. For under 55s, the likelihood of implant failure after two years is even double that of older patients.

"Currently, implants can only be tested on standard testing machines and clinical trials with few subjects do not serve as sufficient evidence. With our human modeling and the simulations, it's possible to put together multiple virtual patient cohorts and calculate a range of implant variations. Numerous factors such as the size of the prosthesis, muscle strength and many more can be factored in," says the engineer. "This will increase evidence because it is possible to analyze the effects."

In the future, medical technology businesses and clinics will be able to license the human modeling that they need for further research and development. The researcher and his team are currently working with an implant manufacturer on human modeling for simulating and analyzing a knee replacement used in cases of bone tumors.

The recent developments on the in silico human modeling platform will be on display at the joint Fraunhofer booth (Hall 3, Booth E74) at the MEDICA trade show in Düsseldorf from November 13 to 16, 2023. On November 14 (11:30 a.m.—12 p.m.), Dr. Okan Avci will be taking part in the trade show's MEDICA TECH FORUM, presenting the topic of "In Silico Orthopedics—Biomechanical engineering of products."